Continuous Inkjet coders (CIJ Coders)

Linx 8900 Series

Spend more time coding and increasing your output with Linx 8900 CIJ printer – the easiest to use Linx printer on the market.

- Remote connectivity to access, monitor and control Linx 8900 printers and receive remote technical support with Linx PrinterNet, a secure, cloud-based service

- Flexible coder prints up to 6 lines of text, numbers, barcodes and logos

- Simple self-service with up to two years between services – no engineer required

- Quick-change fluid cartridges

- IP55 stainless steel enclosure as standard, IP65 option

- Real-time output measurement and line stoppage logs

- Range of ink types and colours

- Date freezing for batch printing, ideal for 24/7 operations

- Variable character spacing improves vision system recognition

- Prompts to ensure correct date and text is added

Simple to insert text or logos into messages

Linx 8940 Series

Designed to support error-free coding with a simple user interface. Quick message creation and selection with a large touch screen. Up to 6-line coding including Data Matrix and QR code printing, with high-speed variants for a wide range of applications. Quick, self-service with minimal intervention enables you to maximize your production line efficiencies.

6-line coder designed for the most challenging coding applications, with IP65 rating for reliable operation. Print speeds up to 9.10m/s.

Linx Printernet

Remote access and control – always connected to your coding.

Linx PrinterNet enables you to remotely access your Linx printers to control them, anytime, anywhere – keeping you connected to your line.

With the Linx technical support team also monitoring your printers, Linx PrinterNet enables us to help keep your printers running smoothly and deliver a remote fast, fault resolution when needed.

You can now view a summary of the performance of your Production Lines, generated from data collected by Linx PrinterNet from connected Linx CIJ printers.

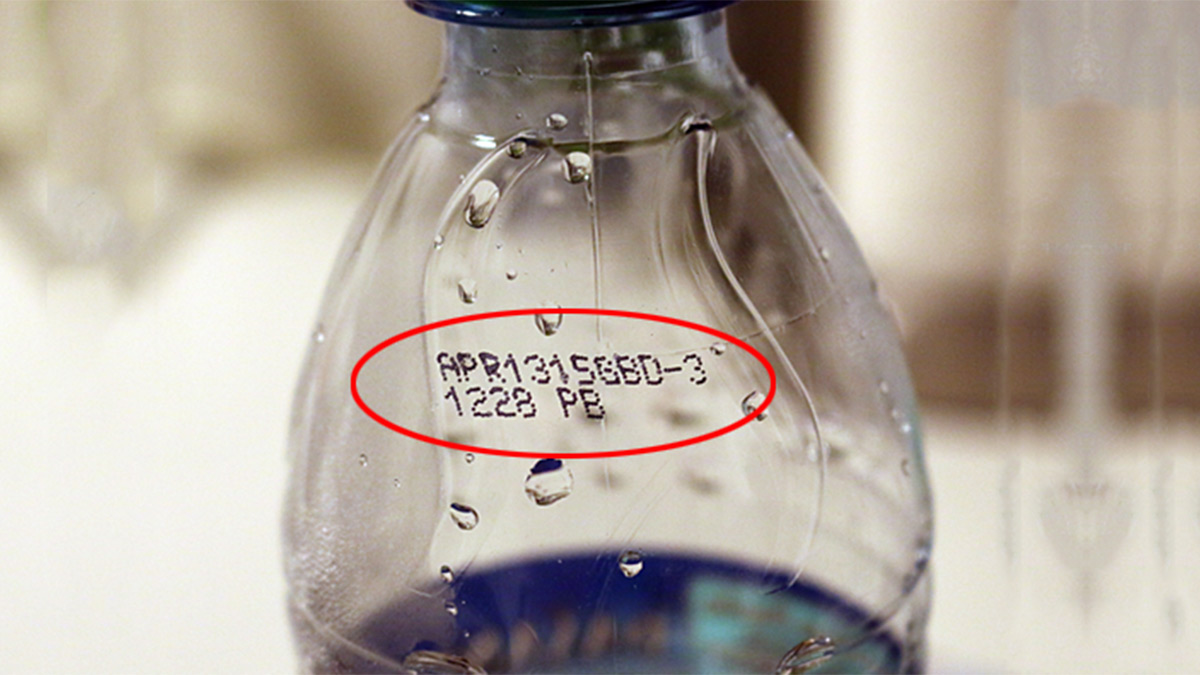

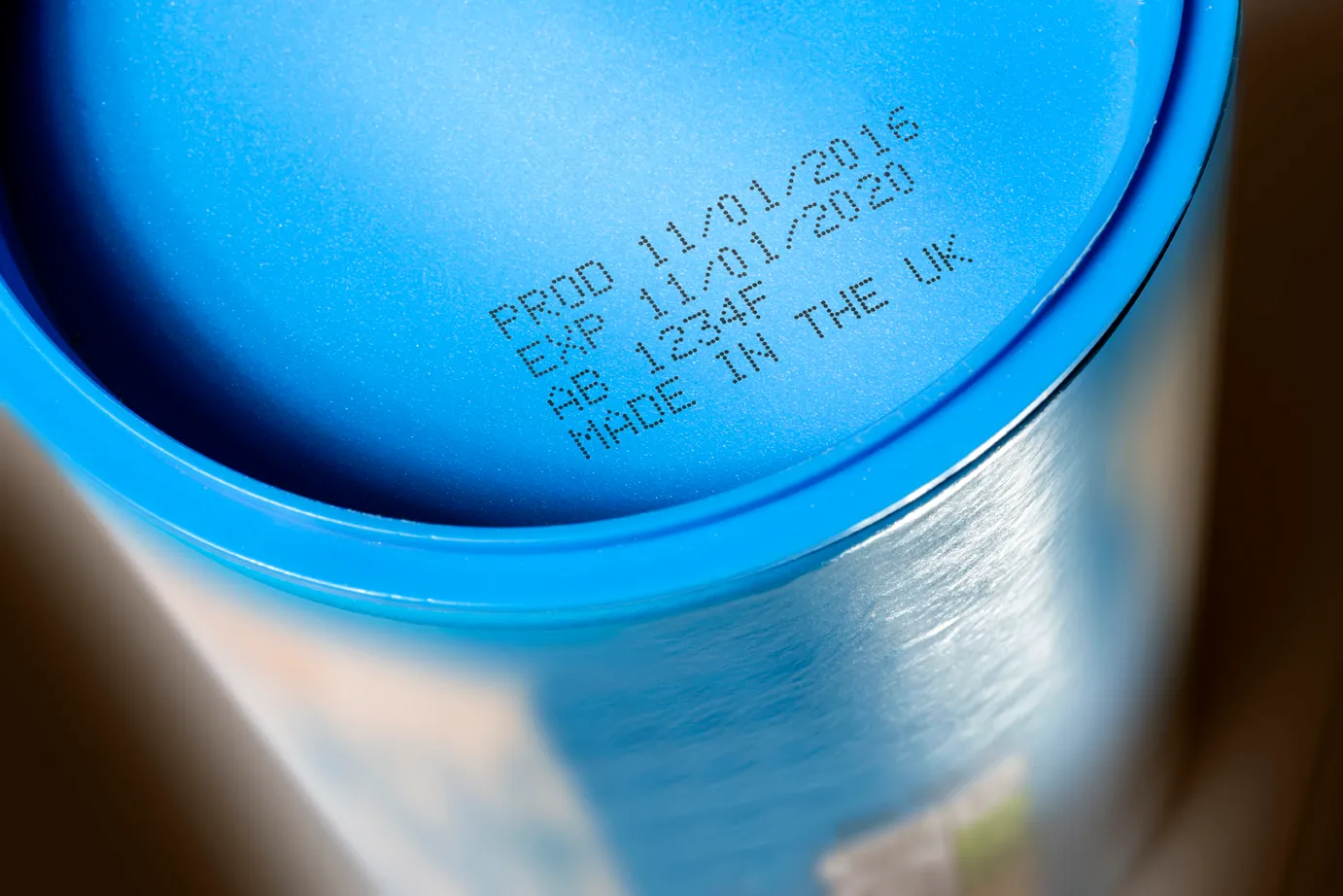

Continuous Ink Jet (CIJ) systems are used to print variable information, such as dates or batch codes, on individual products as they move along the production line – regardless of porosity, size, shape, or texture.