Thermal Transfer Overprinters (TTO)

LINX TT500

The Linx TT 500 is a simple printer designed for printing onto flexible materials including bags, pouches, labels and flow wrap, ideal when coding areas up to 32mm x 100mm.

Low cost of ownership, increased uptime, easy to use.

- Operates without compressed air reducing installation and operating costs while maintaining consistent print quality

- Large range of ribbons to better meet your application and production line printing needs

- Optimised ribbon usage with bi-directional stepper motors delivering more prints per ribbon

- Lightweight, simple, push button ribbon cassette system for quick and easy ribbon changes

- Optimal number of user maintainable parts that are easy to replace

- Easy to set and maintain print quality with electronic pressure control

LINX TT750

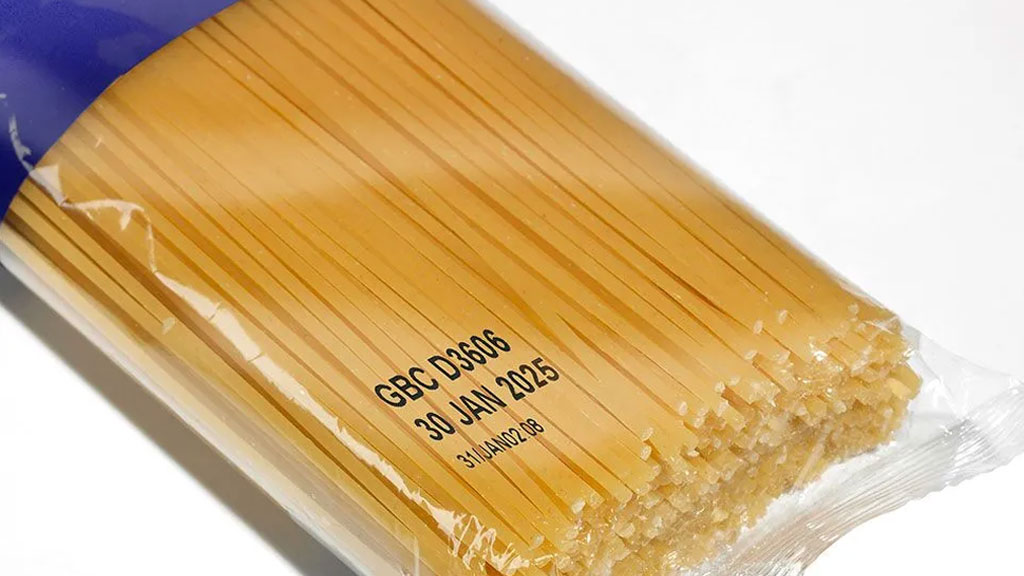

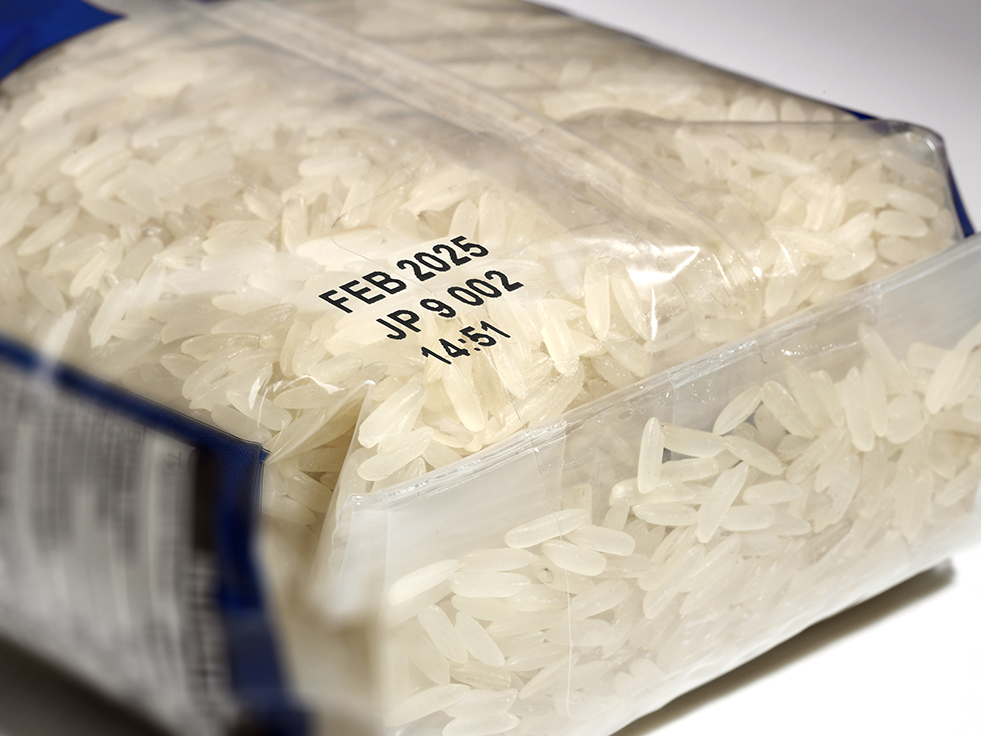

Packaging printing – best before dates and batch codes.

The Linx TT 750 is a simple printer designed for printing onto flexible materials including bags, pouches, labels and flow wrap, ideal when coding areas up to 2.09in x 7.87in

Low total cost of ownership, increased uptime, easy to use.

- Operates without compressed air reducing installation and operating costs while maintaining consistent print quality

- Large range of ribbons to better meet your application and production line printing needs

- Optimised ribbon usage with bi-directional stepper motors delivering more prints per ribbon

- Lightweight, simple, push button ribbon cassette system for quick and easy ribbon changes

- Optimal number of user maintainable parts that are easy to replace

- Easy to set and maintain print quality with electronic pressure control

- Simple cassette system minimises errors during ribbon replacements

- Easy to use colour touch screen – fewer errors and hassle-free operation

Linx TT 1000

The Linx TT 1000 is a simple printer designed for printing onto flexible materials including bags, pouches, labels and flow wrap, ideal when coding areas up to 107mm x 300mm.

Advantages

Low cost of ownership, increased uptime, easy to use.

- Operates without compressed air reducing installation and operating costs while maintaining consistent print quality

- Large range of ribbons to better meet your application and production line printing needs

- Optimised ribbon usage with bi-directional stepper motors delivering more prints per ribbon

- Lightweight, simple, push-button ribbon cassette system for quick and easy ribbon changes

- Optimal number of user-maintainable parts that are easy to replace

- Easy to set and maintain print quality with electronic pressure control

- A simple cassette system minimises errors during ribbon replacements

- Easy to use color touch screen – fewer errors and hassle-free operation

Linx Printernet

Remote access and control – always connected to your coding.

Linx PrinterNet enables you to remotely access your Linx printers to control them, anytime, anywhere – keeping you connected to your line.

With the Linx technical support team also monitoring your printers, Linx PrinterNet enables us to help keep your printers running smoothly and deliver a remote fast, fault resolution when needed.

You can now view a summary of the performance of your Production Lines, generated from data collected by Linx PrinterNet from connected Linx CIJ printers.